| Content: | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Complies with BS 3900;E6, ASTM D 3359, BS/DIN EN ISO 2409.

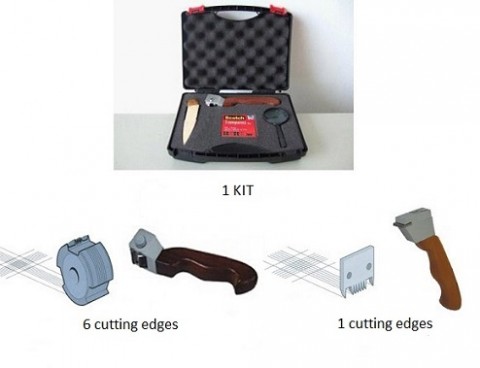

This cutter is used for determining the parallel groove adhesion of one or many coating layers on a substrate, generally a metal panel. Cutter are available in 2 different blade versions, one is a multi-cut blade with 6 cutting edges, another has one cutting edge. The Cross-Cut Tester blades are made of hardened steel alloy. The blades are designed for retaining a sharp cutting edge and reduce the frequency of blade replacement. To choose a right cutter.

Operation When using the 1mm spacing with 6 tooth blades, with the knife edges downward, pull the tool over the painted surface being tested; scratching the coating to the bottom. A second crosswise cut (at an angle of 45° or 90°) will produce a ruled area comprising 25 squares or diamonds. Evaluate the appearance or behavior of the coat of paint after some vigorous strokes with the stiff brush provided, or scratching with a fingernail (partial or complete flaking or peeling, no change, etc.). Also note the condition of the substrate (sand-blasted, primed or with a prime coat, degreased, pickled, etc.). Ordering.

Comes complete with: Cross-Cut Tester kit with blade Magnifier Cleaning brush Plastic carrying case operating instructions one roll of adhesive tape |

|||||||||||||||||||||||||||||||||||||||||||||||||||||